Perhaps you have checked out a aspect of something you have been utilizing and thought about how this part was developed? In that case you have probably viewed the task of your CNC milling and transforming device. These appliances make it possible to make from simple equipment or passes away, to complex decorative tire rims. A CNC milling Companies is based on the first milling equipment of the past. Initially milling and switching equipment necessary a machinist to stand more than them and make certain that practically nothing gone away from endurance. These machines exactly where challenging to put together after which very difficult to keep whilst undertaking their job, but due to technology, they already have not just turn out to be easier to work, however they can create considerably more complex sections.

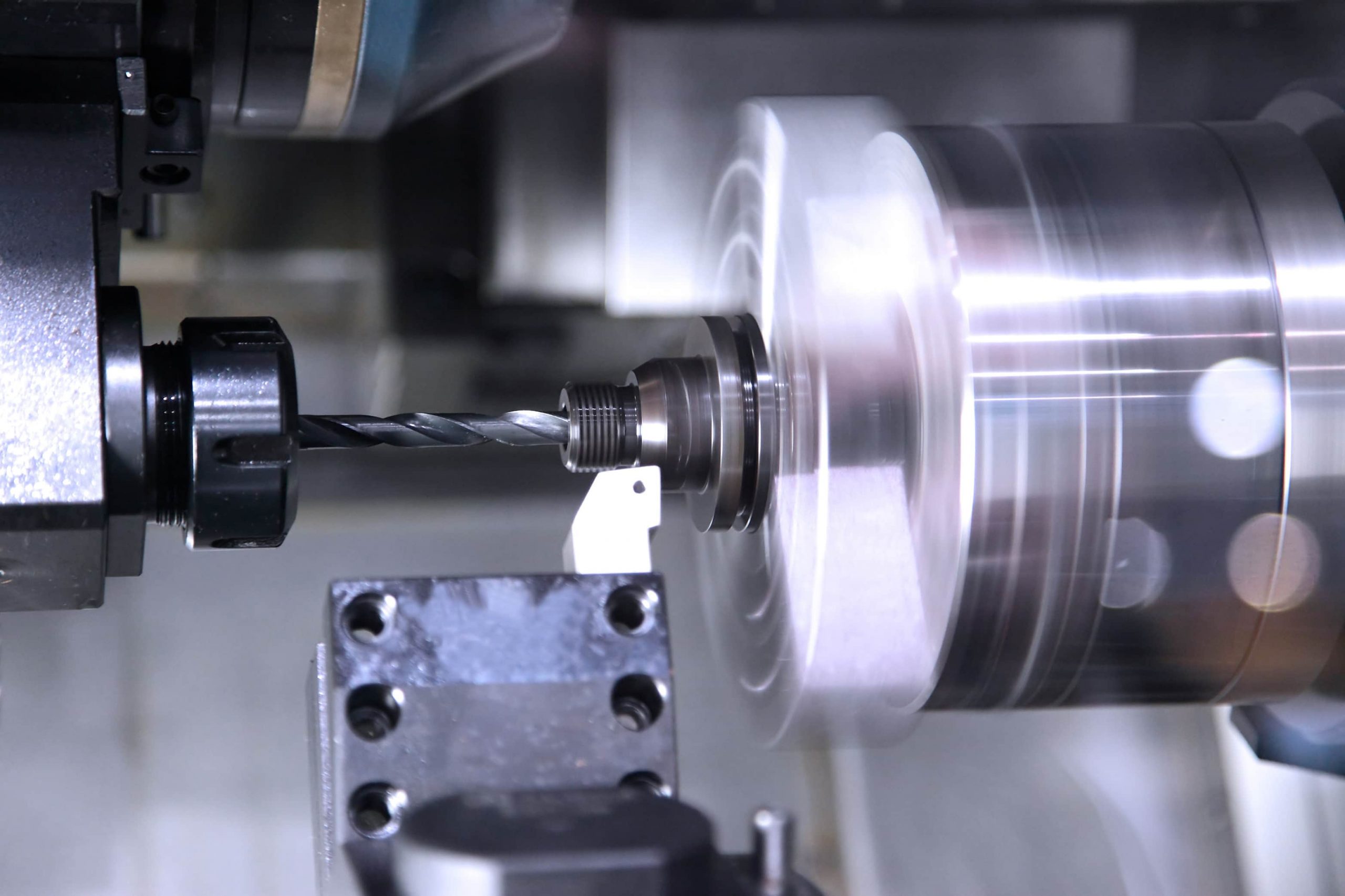

A milling equipment is composed of a number of axles who have various drilling resources connected based on what is to be created. The major distinction between a milling equipment plus a drill press is the drill click holds the part of steel as the drills get the job done. This may not be how a CNC milling equipment and converting functions. Using a CNC milling device the aluminum is shifted to the equipment whilst a drilling water is launched as a way to cool the parts that’s are milled. When the part has to be spun versus the tool, this is known as transforming, comparable to a lathe.

CNC stands for computer numerical manage, which means that instead of by hand establishing the milling or transforming device, A CNC milling device relies on a laptop or computer for set up. This permits for the development of much more sophisticated elements. Along with making a growing number of intricate parts cnc milling companies and transforming equipment are quicker to work once setup. The owner uses a pc to setup the device, and after that merely tracks the equipment.

Well before the development of milling and converting models, a machinist could only operate one machine at the same time, this resulted in an organization possibly necessary a lot of machinists or the level of components they could end up was constrained. This both cost the organization additional money to get many people to use the devices or they shed funds by being unable to turn out much more sections. Considering that the usage of this computer technology is now more widespread the sole limitations a business has is the amount of CNC milling models readily available. Furthermore by having pHs on the method increasingly more in depth pieces can be produced.

Recent Comments